As I want to lost wax cast a lot of the parts for the Class 70 bogie assembly, it made sense to get the master parts for the external detail 3d printed.

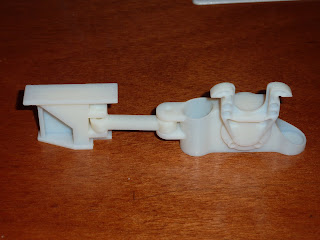

Here are some of the suspension parts 3d printed ready to make silicone moulds from. These have been scaled up to allow for metal shrinkage in the casting process.

I had these printed by 3dprintuk and I think they have come out very well. Turn around time was only a few days once the files were finalised. The only hitch came when the post office lost them. Still they found them in the end and the parts turned up ok a couple of days later.

These were printed on an Objet machine using a printable photo polymer process. This in my opinion gives much better resolution and surface quality than some of the other technologies in common use.

No comments:

Post a Comment